What Does the Term Cable Connector Mean?

In industrial automation and related fields, a cable connector is a key component that enables the safe and efficient transmission of electrical power, signals or data between machines, control systems or devices.

At binder, the term “cable connector” covers both overmoulded and field-attachable solutions, tailored to specific operating environments, electrical standards and mechanical load requirements. In doing so, they make a crucial contribution to system reliability and to maximising plant availability in demanding industrial applications.

A connector fundamentally consists of two parts:

- the cable connector, to which the cable is permanently attached or assembled,

- and the corresponding panel or device connector, which is permanently mounted on a machine, housing or device.

Only the interaction of these two components allows for a functional, safe and detachable connection.

What Are Cable Connectors?

Cable connectors are electromechanical components that provide a detachable interface between cables and other components or systems. Their main purpose is to ensure a stable electrical connection, prevent signal interference, and protect the contact points against mechanical wear, dust, moisture, and chemical influences.

What makes cable connectors distinct from flange connectors is that they are predominantly used externally. As a result, they are more exposed to environmental factors such as dirt, moisture, or mechanical stress than fixed flange parts. Their design must therefore be particularly robust, reliable, and tailored to the respective application.

They are indispensable for modular system construction, straightforward maintenance, and scalability in industrial environments.

binder offers a wide range of cable connectors, including:

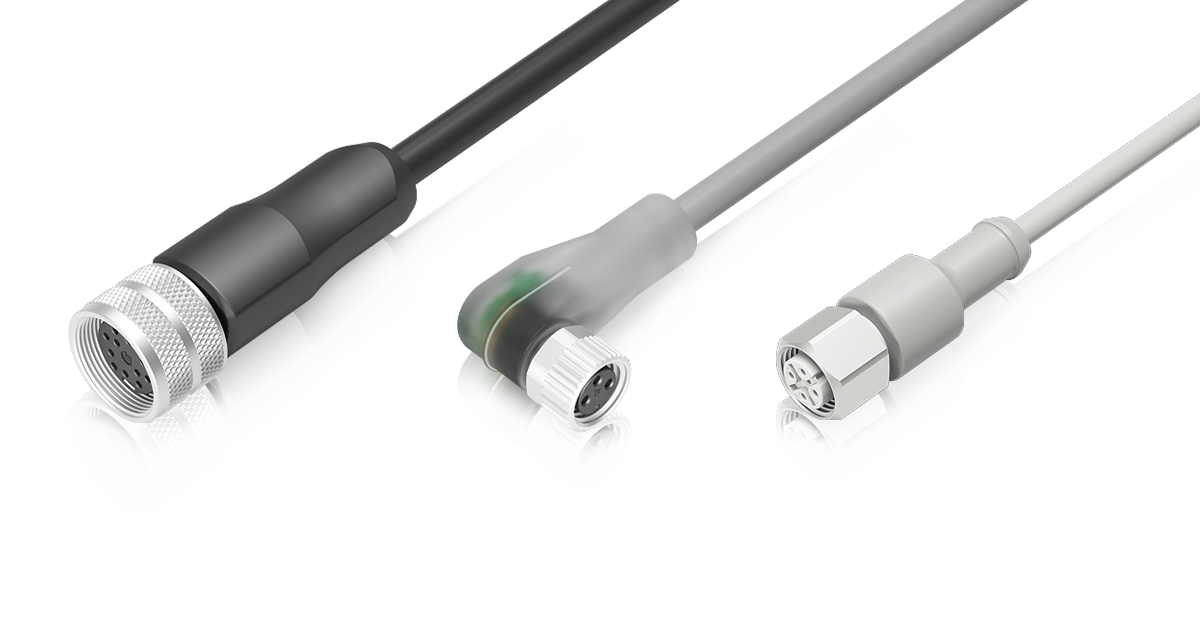

Overmoulded Cable Connectors

Overmoulded connectors are factory-assembled and therefore ready for immediate use, as they are already prepared for connecting the cable to the device. This design ensures maximum durability and provides a high level of protection against the ingress of foreign particles and moisture. Overmoulded cable connectors are particularly suitable for applications where strong resistance to environmental influences, mechanical stress, and vibrations is essential.

Single-ended cordsets

Overmolded on one end with exposed wire on the other – commonly used for direct wiring into control cabinets or machinery.

Products

Double-ended cordsets

Overmolded on both ends, designed for plug-and-play convenience in modular or mobile systems.

Products

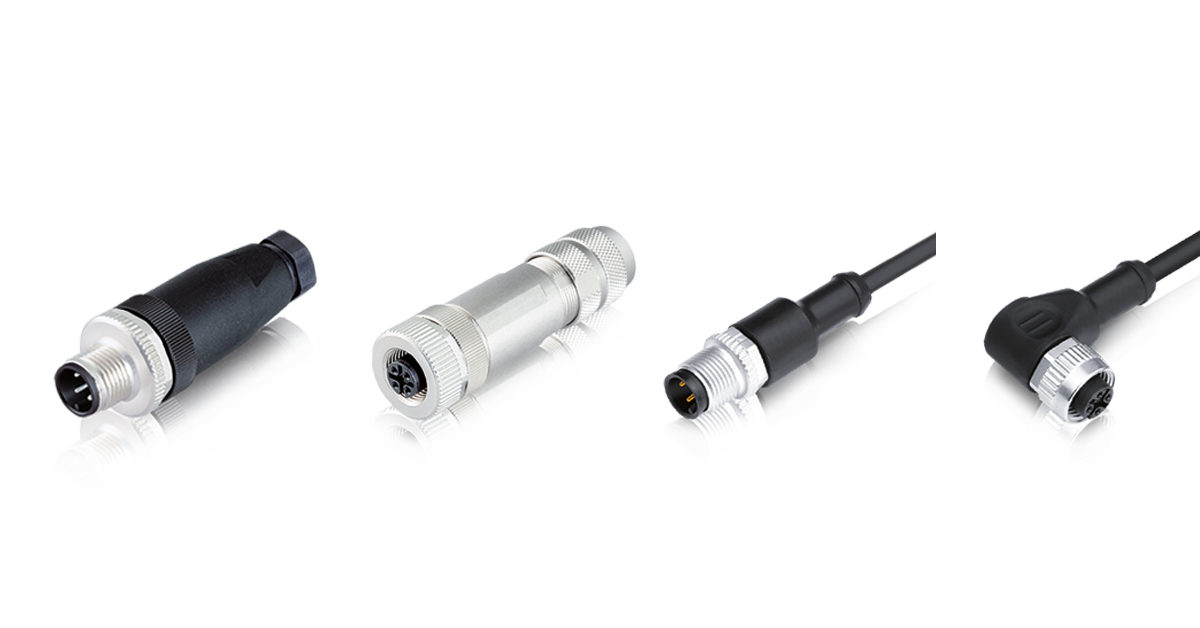

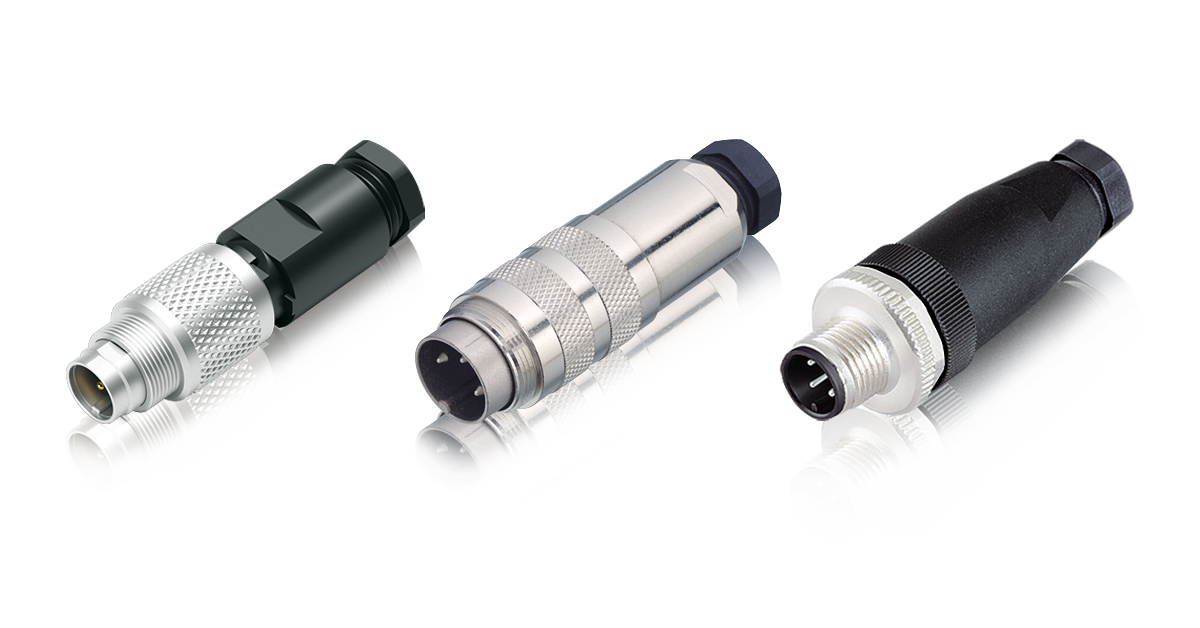

Field Wireable Cable Connectors

Field wireable connectors offer flexibility in installation and are ideal for custom-length cables or last-minute adjustments. They can be assembled on-site, which is a major benefit in complex or retrofitted systems.

Products

Types of Cable Connectors

The binder portfolio of cable connectors covers a wide range of functions – whether for power supply, signal transmission or data communication. All connectors are designed to ensure safe, reliable and efficient performance under a variety of operating conditions.

Power Connectors

For the transmission of electrical energy, often under high load or in harsh environments.

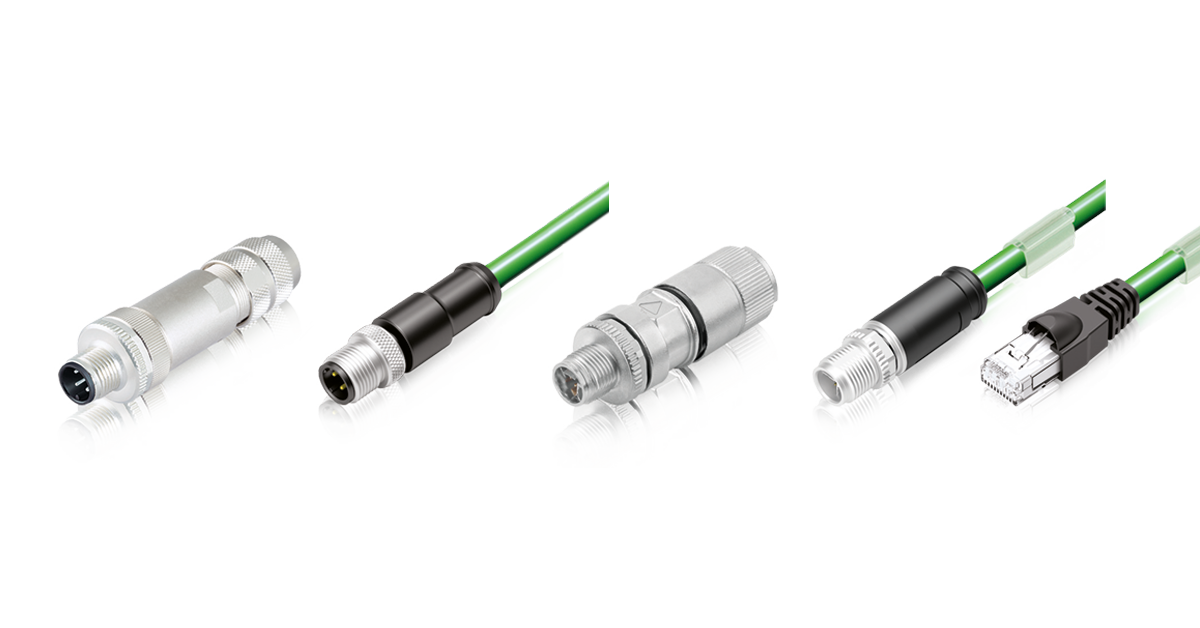

Data Connectors

For fast, interference-free data transmission, including Ethernet and fieldbus systems.

Key Features, Benefits & Quality Standards

At binder, we prioritize high performance and reliability across all cable connector types. Our products are developed in accordance with international quality standards and thoroughly tested under real operating conditions. . From precision manufacturing to innovative material selection, every connector is engineered to deliver long-lasting performance.

- High mechanical durability and vibration resistance

- Sealing options up to IP67, IP68, and IP69K for demanding environments

- Locking mechanisms including M12 screw-lock, bayonet, and push-pull

- UL, CSA, and other international certifications

- Temperature, UV, and chemical resistance

- Custom overmolding solutions available

These characteristics make binder connectors the first choice worldwide for critical applications.

Applications & Industries

Cable connectors are used in nearly every modern industrial and commercial system. From fully automated factories to precision-driven medical technology, they serve as the physical backbone of electrical and data connectivity.

- Automation: For sensors, actuators and I/O systems

- Robotics: Vibration-resistant connectors for axis movements, end effectors and production cells

- Agriculture & Smart Farming: Robust, weather-resistant designs

- Transport & Railway Technology: Resistant to vibrations, environmental influences and extreme temperatures

- Medical & Healthcare: For high-precision, low-interference applications

- Energy & Renewable Energies: Supporting sustainable infrastructures

- Food & Beverage Industry: IP69K options for cleaning and hygiene areas

binder cable connectors integrate seamlessly into these diverse fields of application, ensuring efficiency and system availability.

Future Trends & Innovations

As industries evolve toward smarter, more compact, and faster systems, cable connectors must evolve as well. binder continues to innovate to meet future challenges in automation, robotics, and IIoT applications.

- Miniaturization: Solutions for tight spaces and lightweight designs

- High-speed data: Supporting modern industrial Ethernet standards

- Improved EMC shielding: Critical for data integrity in industrial environments

- Tool-free locking systems: For faster maintenance and reduced downtime

- Integrated intelligence: Exploring sensor-enabled and diagnostic-ready connectors

How to Choose the Right Cable Connector

Selecting the correct connector is essential for system safety, longevity, and performance. The right choice depends on the electrical and mechanical requirements of your application. Key considerations include:

- Cable connector type (Single-ended cordset, double-ended cordset, field wireable)

- Application (power, signal, data, hybrid)

- Number of contacts and contact arrangement

- Gender (Pin/ Socket)

- Locking type (e.g., M8, M12, 7/8", etc.)

- Current rating and rated voltage

- IP protection class for environmental demands

Use our Connector Compass and Product Filter Tool to quickly narrow your options, or contact us for direct assistance.

Ready to Get Started?

Whether you're integrating connectors into a new automation line, upgrading existing systems, or building custom machinery, binder provides durable, high-quality cable connectors that meet your specific needs.

Explore Cable Connectors to find the right solution today.